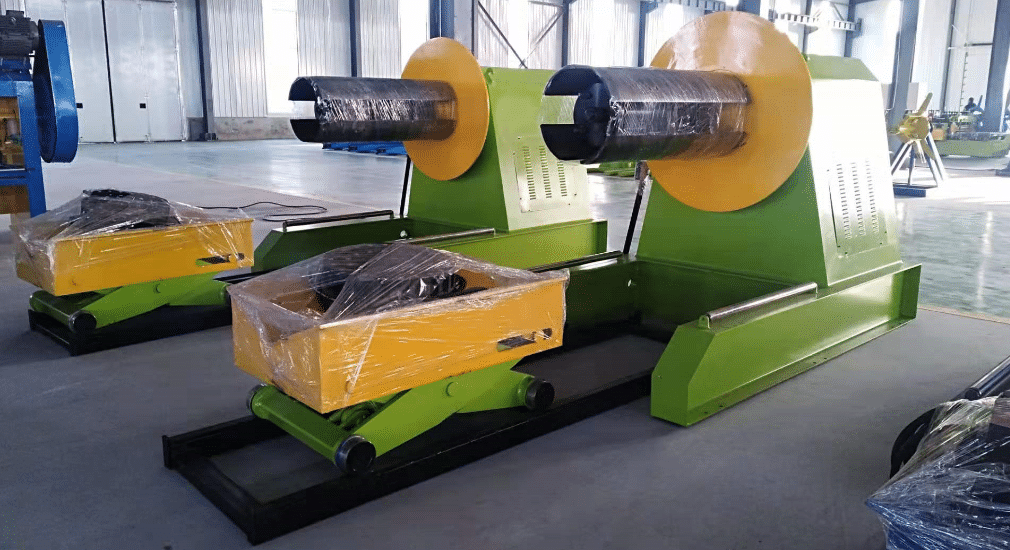

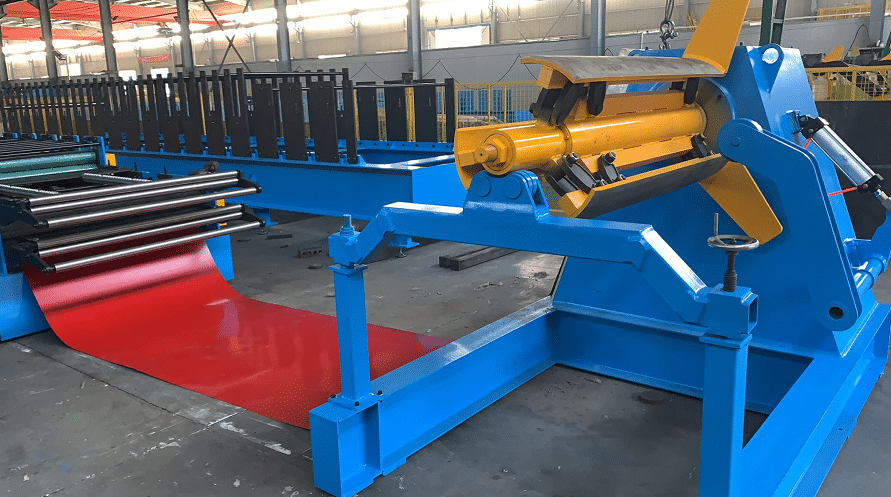

7 Ton hydraulic decoiler for roofing forming machine is designed for metal roofing sheet production.

Hydraulic decoiler, which it is designed to support the coil and provides tension to the steel belt, is an decoiler composed of a frame, a main shaft, an expansion and contraction drum, and a brake device. And according to the market needs, we have 1.5 Ton, 3 Ton, 5 Ton, 10 ton and more types design for you too choose. In this article, mainly we show the 7 Ton hydraulic decoiler for roofing forming machine. As for the metal roofing sheet machine, the shaft is longer to Max 1650mm or more and then thickness to 1.0mm or more. The weight we design for 7 Ton, as to the loading car, you can choose to add or not.

7 Ton hydraulic decoiler for roofing forming machine basic elements and how it is built:

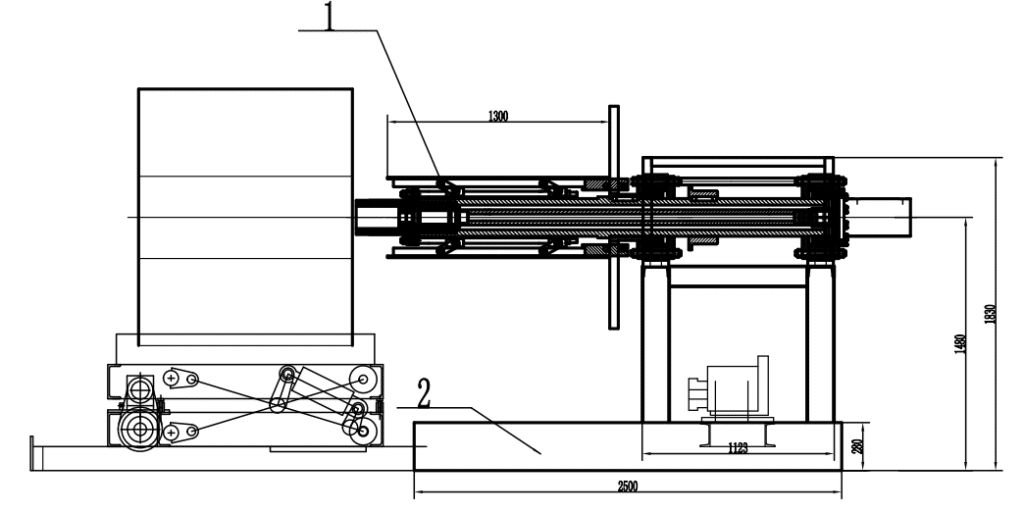

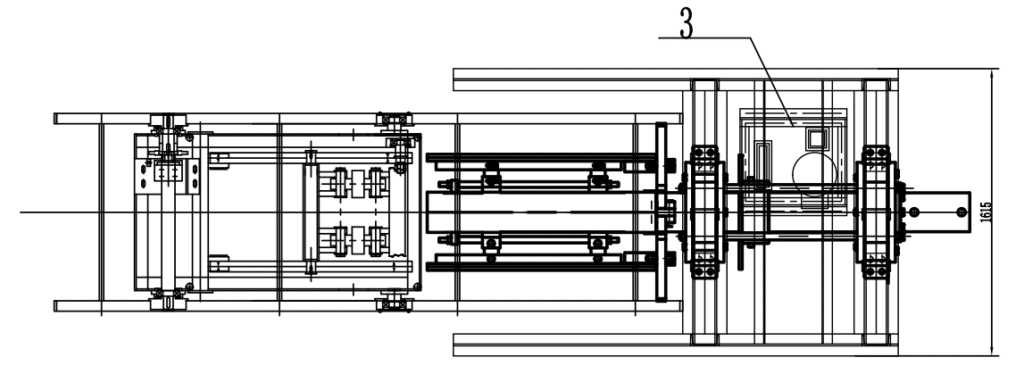

a). The main frame: It is made of section steel, A3 steel plate, #45 steel forged bearing seat after assembly welding, and qualitative annealing treatment is not deformed; two bearing seats are made by boring at one time to ensure the concentricity of the main shaft installation. Produce radial runout.

b). Spindle: It is made of a 40Gr round steel drill with a diameter of 85mm through hole, quenched and tempered and then refined. The working surface has a diameter of 190mm and a load-bearing capacity of 15 tons.

c). Expansion and shrinkage reel: adopts slider type push-pull expansion reel form; four arc-shaped plates, wire-cut slider pair, expansion and contraction diameter Ф460~Ф520; effective working length 1300mm, integral mandrel ensures that the reel expands and shrinks Time concentricity, hard chromium plating on the surface of the reel.

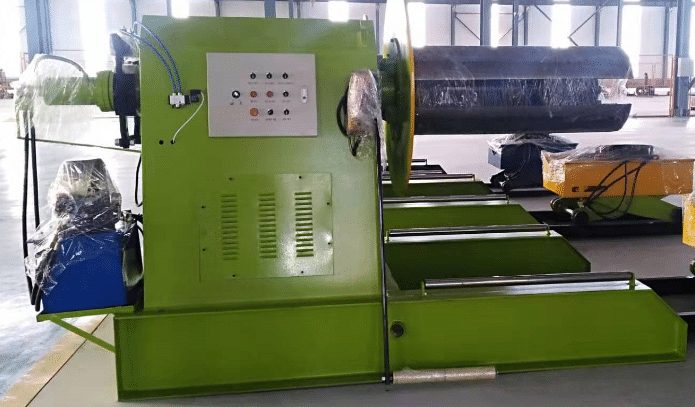

d). Brake device: using pneumatic disc brake components, the brake force can be adjusted, the brake is tight when parking, and the brake is running when driving, to ensure that the standby and power-on states will not loosen, so as to avoid scratching the surface when loosening.

e). Hydraulic power: push-pull expansion and contraction mandrel: hydraulic cylinder model specification: FA-Ф125×130mm, with rotary joint oil supply mode; material lifting hydraulic cylinder FA-Ф63×600 mm.

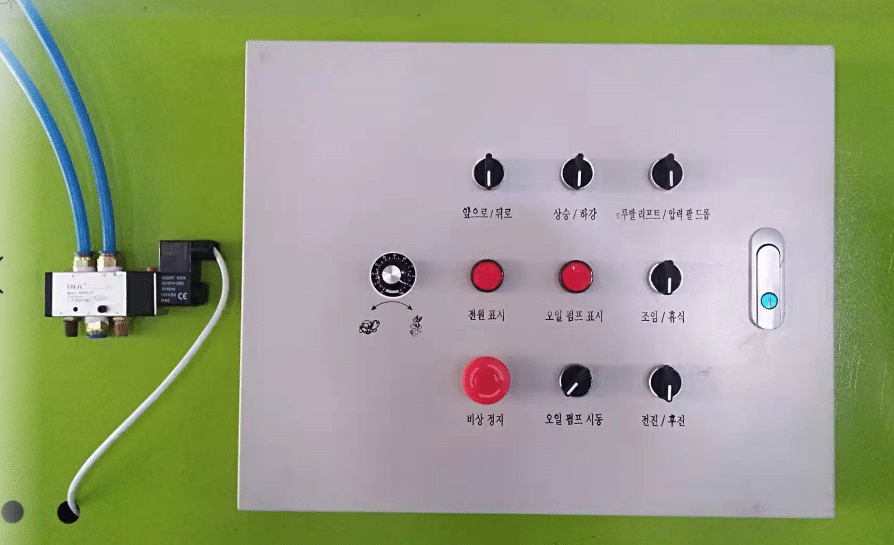

As to the control panel, we can customize it according to your own language.

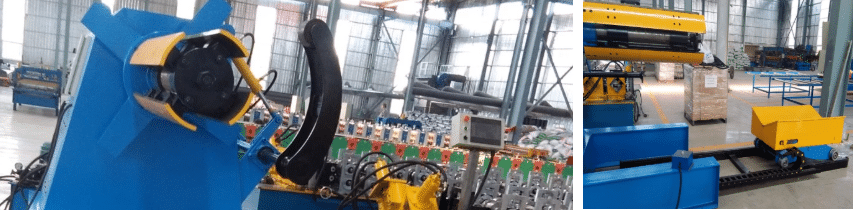

7 Ton hydraulic decoiler for roofing forming machine, when it works together with the metal roofing sheet machine, it can match the speed with the metal roofing sheet machine and let the rolling machine works easily and fast.

And the loading car can feed the coil to the machine center to center and do the production using less workers meanwhile safely.

And for the decoiler, if you want to know more information, please contact us at any time.

Here is the machine working video for your reference: