Manual adjustment C purline, U purline rolling forming machine

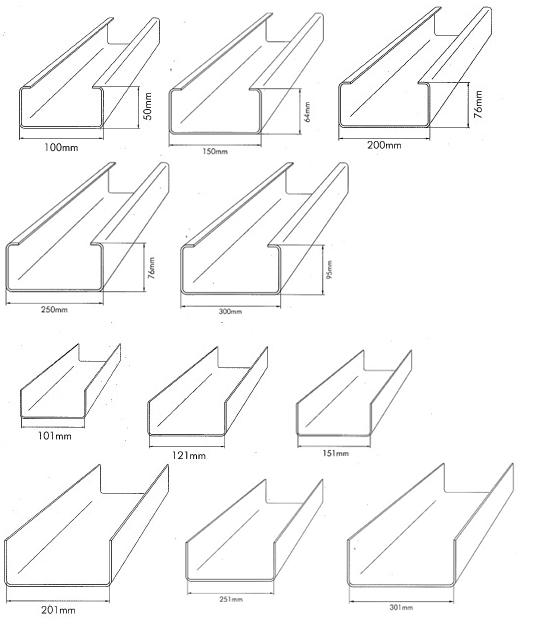

Manual adjustment C purline, U purline rolling forming machine is designed to make the C purline, U purline in bath fully automatically. The Purline rolling forming machine can reach the speed of 15 meter per minute including the punching. Material thickness could be from 1.2-3.0mm, as to the bottom size could be from 80 to 300mm.Here are some popular sizes for your reference:

Manual adjustment C purline, U purline rolling forming machine pictures for your reference:

How to change sizes from different C to different U by manual work?

For the different C purlines that means the coil widths are different. Expect adjusting the input coil width, you also need to adjust the spacer and change the cutting blades. All the process is around 2 hours .

As to the input coil width and leveling and punching as follows:

Manual adjustment C purline, U purline rolling forming machine parameters for your reference:

1). Inside diameter coil is 450 – 550mm

2). Coil Width is 600 mm

3). Capacity:5 ton

5). Hydraulic expansion

6).Automatically feeding

7). Hydraulic, inner tight

8).Hydraulic power: 3 kw

1).Roller station: 12 steps

2). Roller material:GCR12 Mov

3).Shaft material:45# steel,Outer diameter:

4).Transport:Transport by Gear

5).Forming speed: 8-10m/min

7).With yellow safety guards

5).Voltage: 415v 50hz 3phase or customized.

Cutting system

1).Blade and mold material: Cr12 steel with quenched treatment

2).Cutting system:advanced hydraulic drive, automatic cutting

6.Control system:PLC control

Hydraulic system

1). Advanced hydraulic system

2). Power:7.5kw

8.Punching

Punching hole as drawing

For the C purline, CU purling machine, now mostly we recommend the fully automatic type which we will introduce in next article. Compared with fully automatic, the manual adjustment cost is more lower and it is more during. This type is good for those who is professional about the machine operation.