ZhongTuo Machinery designs and manufactures many floor deck roll forming machines that can produce standard metal decks or steel decks and these decks are widely used in various buildings. There are many kinds of machines making floor decks for different uses, for instance, some floor deck forming machines are equipped with embossing tools while some others are not. If you have different needs of the floor deck machine, we can offer you the customized service. So please click here to contact us at any time, we are delighted to cooperate with you!

Here is a video of our machine for your reference:

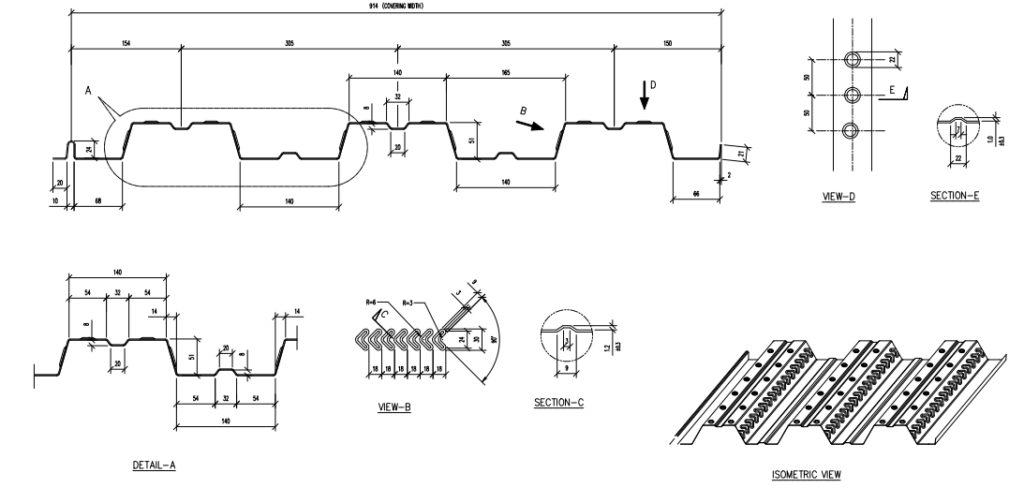

Drawing profile of floor decks:

There are many kinds of metal floor deck sheets. In the picture, on the top is the model type of metal floor decks with three waves and four waves. On the bottom is the embossed type.

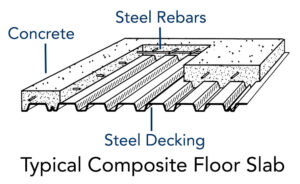

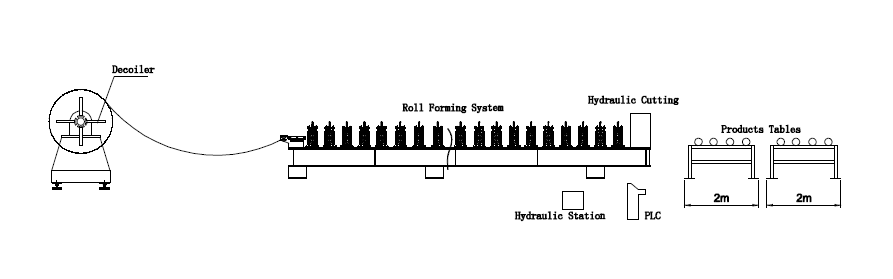

Picture of finished metal floor deck and the machine:

Advantages of metal decking rolling forming machine:

- ZT structural floor and facade rolling forming machine can produce the floor decking in the speed of 15 to 20 meter per minute.

- We can make the perfect shape when overlapping, it can match one and another easily.

- The machine we design using 43 roller stations to make sure the shape is good and fixed well.

- Machine we use 30mm thickness middle plate.

- Easy for installation, all electrical components we use the Simens Brand

Working process:

Technical Details

| Machine Specifications | |

| Weight | About 15000kgs |

| Size | About 16m x 1.8m x 1.5m (length x width x height) |

| Suitable Raw Material | |

| Material | Galvanized or Galvalume Coils |

| Thickness | 0.8-1.2mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Diameter of forming rollers shafts | 95mm |

| Roll Forming Speed | 10-15/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 3x11kw |

| Hydraulic unit motor power: 5.5kw | |

| Electric voltage | According to customer’s requirement |