Metal roof tile rolling forming machine

Metal roof tile rolling forming machine is designed to make metal tiles in batch fully automatic for enhancing production rate. As to the roof tiles are to keep out rain. And traditional made from locally available materials such as slate and terracotta. And modern materials such as concrete, plastic and Metals.

Metal Tile is very special and consist of a high percentage of recycled material and is 100% recyclable. And the Metal Roof Tile is also lightweight, can be installed on top of an existing roof. it’s very useful for a large and old structures( such as wooden structure). It is interlocked, so it provides increased wind resistance when compared with other roof materials. BELI® have developed almost 50 types of metal roof tile roll forming machine for different requirements.

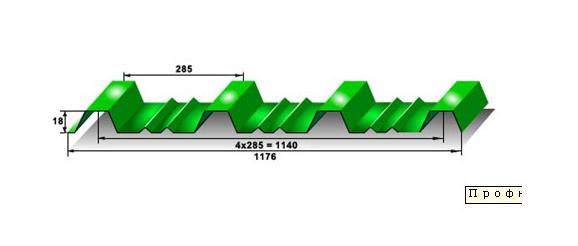

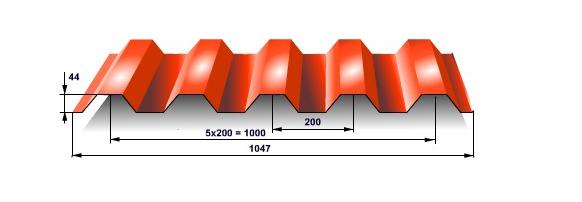

Here are some drawing profiles for your reference:

Metal Roof tile roll forming machine is also called step tile roof roll forming machine, glazed roof tile roll forming machine, 3D roof tile roll forming machine, etc.

Metal Roof tile roll forming machine:

Metal Roof Tile Machine Components, hydraulic Uncoiler, Feeding and Guiding Device, Roll Forming Mills, Punch Step System, Cutoff Unit, Collection TableControlled Panel, Hydraulic Stations.

Here is the hydraulic decoiler for your reference:

- Hydraulic expansion, Electric Uncoiling

- Coil I.D: 480-560 mm

- Coil O.D: 1200 mm

- Uncoiling Motor Power: 5.5KW

- Hydraulic Motor Power: 3 KW

- Load Capacity: 5 Ton( 10 Ton as an option)

- Uncoiling Speed: 20m/min, but synchronous with the main roll forming machine

Roll Forming Machine

- material Thickness: 0.3-0.8mm

- Forming Steps: 18

- Driven Motor Power: 7.5KW

- Line speed; 4-6m/min

- Rolls Material: ASTM 1045, hardness treatment and chromed

- Shaft Material: ASTM 1045, 76mm O.D

Punching steps and Cutting System

The Punch step and cutting system is separately,we also have common bed design.

Punch mould and cutting blade material: Quality CR12

Hydraulic Motor Power: 11KW with storage tank

Workers can set the length of steps, tiles and the quantity on touch screen