Applicable Material Thickness:1.0-3.0mm yield strength≤G345Mpa

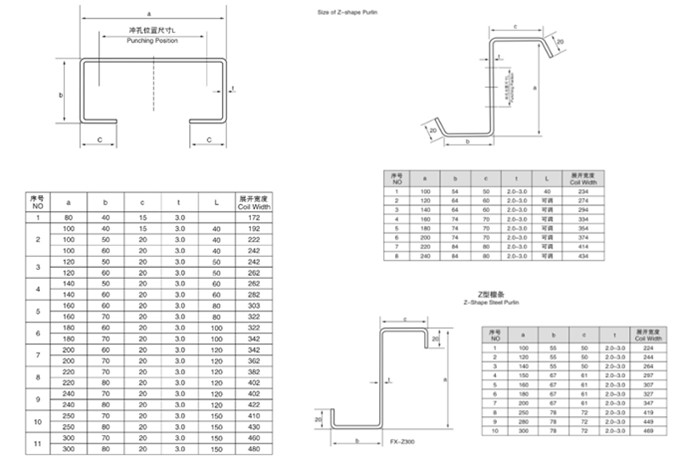

Range of Cee purlin Height:40-80mm±1.0

Width:80-300mm±1.5

Lip:10-20mm±0.5

Forming station 16 stations

Forming Rollers GCr15, heat treatment and hard chrome-plated ,HRC55-58

Main shaft material S45C, heat treatment HRC42Φ80mm

Leveling roller 5 rollers

Pinching device 2 Steps of pinching

Punching hole Punching after forming to make sure the accurate punching.

Totally 4 funching stations. 3 bottom punching. And one side punchine.

There are 9 punching dies. For different profile, please change to realted dies.

Cutting after forming, stop to cutting

Rolling forming speed: 18m/min

If with punching, for example profile G, the most complicated, the speed is around 8m/min.

15KW, Siemens brand

1.0 double line chains

PLC Siemens brand

Approx.10000×1400×1600 mm

Approx.9500kg