Suitable Coil Thickness: 1.5-2.5 mm

Suitable Raw Materials: Galvanized steel plate

Yield Strength: ≤235Mpa

Line Speed: about 10-15m/min

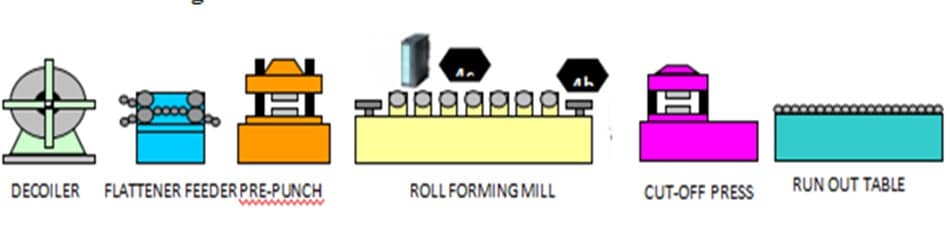

2 ton Manual decoiler 1 set

Punching system 1 set

Leveling machine 1 set

Coil feeder 1 set

80 tons punching machine 1 set

Mold 1 set

Roll Forming 1 set

Hydraulic Cutting 1 set

PLC Control System 1 set

Hydraulic Station 1 set

Run-out Table-(Un-powered) 1 set

Feeding and leveling rollers:

Rollers: 4 steps, leveling Rollers: 9pcs

Diameter: 80mm

Leveling thickness: 3.5mm

Feeding speed: 20m/min

Drive type: gear

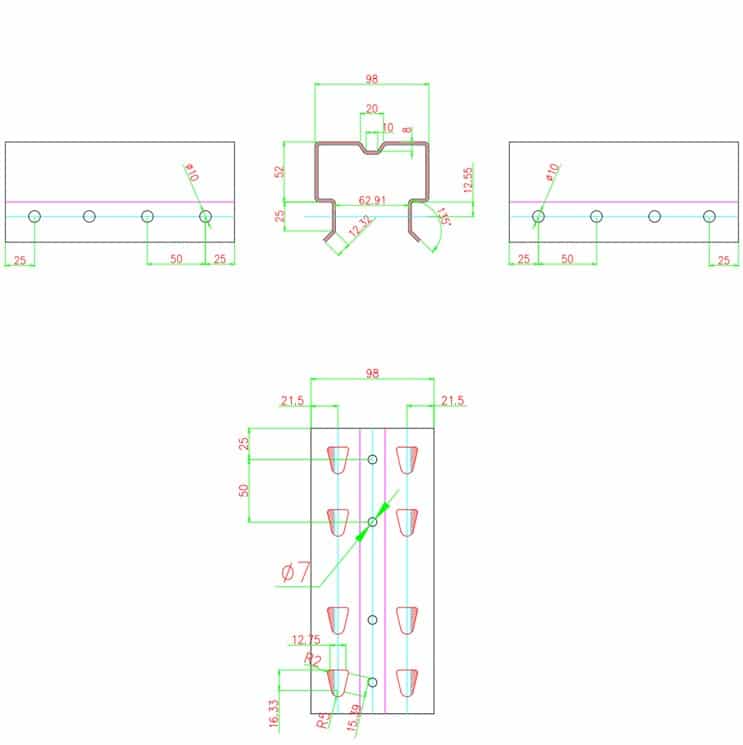

1)Model: Yx12,32x77x98mm

2)Feeding width: 300mm

3)Working speed: 10-15meters/min(Not Including cutting time)

4)The thickness of the panel :1.5-2.5mm

5)Controling method: PLC

6)2 ton manual decoiler 1 set

7)Leveling machine one set

8)Leveller motor 3kw

9)Servo motor feeder one set

10)Servo feeding motor:1.8kw【Brand Anchuan】

11)80 tons press machine, Brand is Yangli

12) punching machine and mold

13) Roller station 23

14) Roll material Gcr15 steel after finishing, quenching HRC58-62 ° C, surface chrome treatment

15) Shaft material and shaft diameter 45# steel finishing, shaft diameter is¢76mm