Roofing Sheet Roll Forming Machine

Introduction of R-Panel Roll Forimg Metal Machine:

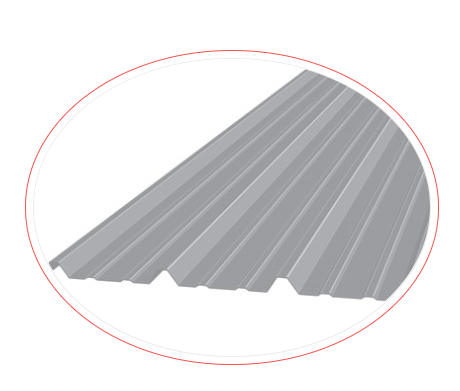

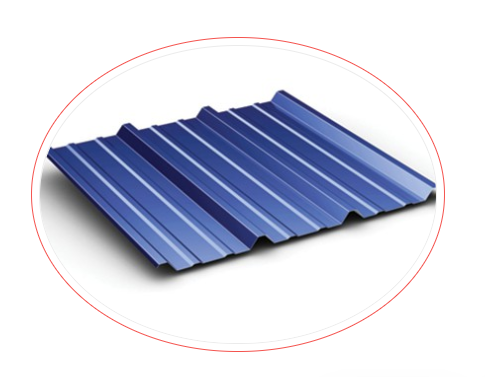

R-Panel metal roofs are the long-lasting and beautiful stunning metal roofing option. They are  easy to install and this course cuts down on labor, time, and disposal costs.These R panel roofs are available in many different colors. R-Panel/PBR-Panels are very popular for both residential and commercial roofing systems.

easy to install and this course cuts down on labor, time, and disposal costs.These R panel roofs are available in many different colors. R-Panel/PBR-Panels are very popular for both residential and commercial roofing systems.

R-Panel Metal Roof is built with 36-inch-wide interconnected metal panels. These metal roof types feature overlapping seams which limit water infiltration, but the exposed fasteners can be a point of weakness. Zhongtuo is one of the leading R panel metal machine manufacturers, and specialized in the designmanufacture the roll forming machines, and PRB panel roll forming machine.

Rib type roll forming machine

PBR”Panel stands or Purlin Bearing Rib Panel is far better to the “R”panel for most roof and siding wall applications.These PBR-Panels include a larger overlap section (purlin bearing leg) between panels that give the metal roofing sheets more strength. R-Panels & PBR Panels design for commercial, industrial, and steel frame building applications.

The primary difference between the R-Panel and PBR-Panel is the Purlin-Bearing Leg on the PBR-Panel. This leg provides better support for roof applications.

Standing Seam Metal Roof Machine

The standing seam model is located at the highest point of the roof. The standard metal roof type for very large projects, standing seam roofs are very well regarded in the commercial roofing industry. Standing seam roofing panels are defined as a concealed fastener meta panel system that features vertical legs and a broadflat area between the two legs.

Standing Seam Types: SNAP-LOCK

MECHANICAL LOCK BATTEN PANEL

NAIL FLANGE/FASTENER FLANGE

Metal Roofing Machine

·Summary R Panel Roofing Machine

1.Material: Galvanized Coil and Color steel coil

2.Material Thickness:0.3-0.8 mm

3.Main roll forming machine Power:7.5KW

4.Forming Speed: 12-13m/min

5.Feeding width: 1000 mm/1250 mm

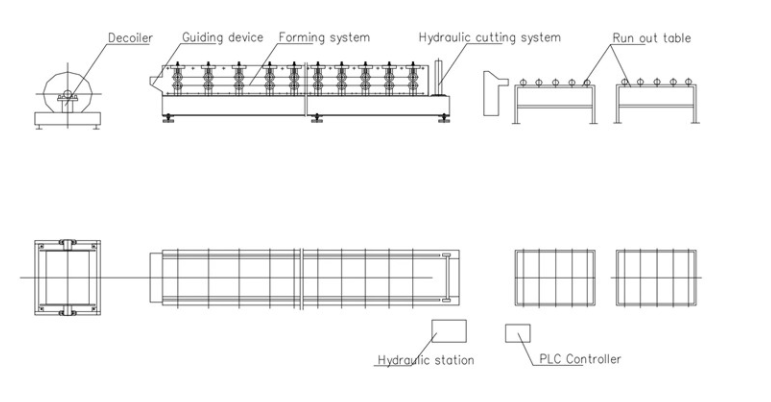

·Main Parts high rib roofing panel roll forming machine

1. Manual Decoiler

2.Feeding Guide

3.Manual slitting device

4. Roll Forming System

5.Hydraulic Cutting unit

6. Control system

7.Output table

·Working Flowing Metal Tile Making Machine

Manual Decoiler → Feeding → Roll Forming → Cutting → Output table

Machine to Make Metal Roofing Decoiler

Decoiler Type: Manual; 5 Ton

Loading capacity:Impassive to expanding

Roll Forming system with the feed panel unit

Axis Diameter: 75mm

Forming Roller station:18 Groups;First grade 45# steel

Main Axis material:heated and quenched; First grade 45# steel

Roller material: Hard Chrome Coated;heated and quenched

Forming Speed:10-15m/min

Drive Type:1”Chain of transmission

Chain size:Japan CHOHO 100#

Welded structural steel:Machine Frame stand;thickness 10 mm

Hydraulic Stamping&Cutting Device

Cutting type:Hydraulic stop cutting

Hydraulic pump power:4 KW

Hydraulic pressure:12Mpa

Hydraulic Blade &cutter material:Cr12, quenching process 58-62

Cutting length tolerance:10m±2mm

Electrical System:PLC system Japan Panasonic

Length Controller:Encoder Japan KOYO

Operation:MGCS Touch Screen

Inverter:Japan YASKAWA

Voltage:380V/50Hz/3P