Shutter Door Slat Roll forming Line

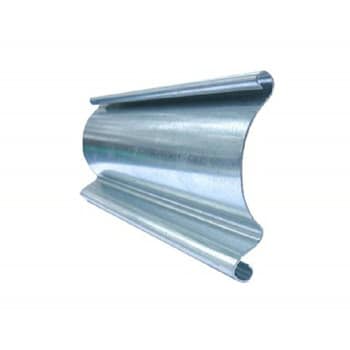

Compared with traditional door, the advantage of roller shutter door is different close or open method. It is by raising up and lowering down, but traditional door is by rotating from 0-90 degress, and the ending of a roller shutter is a roundel along which the shutter door will be rolled when raised up.so our shutter door slat roll forming line become more and more popular.

here is detailed introduction of our shutter door slat roll forming line:

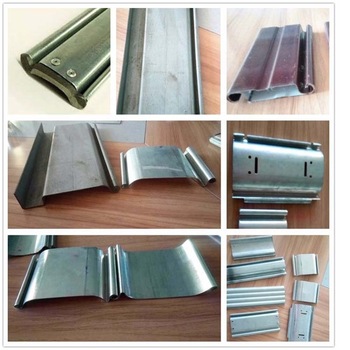

Because of the needs for production of shutter doors, our shutter door slat roll forming machine has been designed and built. The raw material of slat can be galvanized steel strips, prepainted steel strips and some occasions alloy aluminum strips as well. This roll forming line is technically capable to produce shutter door slats with any lengths available and effective widths customizable from metal with thickness 0.6-1.2mm ( heavy duty shutter door slats up to 2mm thickness).

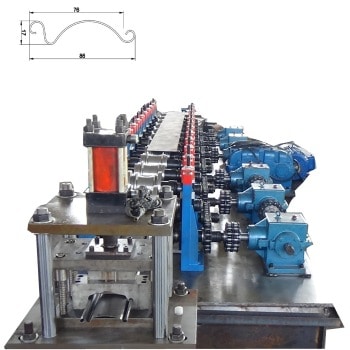

shutter door slat roll forming line consists of: decoiler, a roll fomer, transmission system, a punching tool is optional for punching slots on some types of shutter door slat, a cutting tool (both a hydraulic cutter and a fly-saw cutter is optional), a PLC control cabinet, a hydraulic oil pump station and finish slat runout tables.

Technical parameters of shutter door slat roll forming line:

- Suitable coil weight: Max 3ton;

- Suitable raw material: Galvanized Steel or Prepainted Steel strips;

- Inner Diameter of coil: φ 450—520mm;

- Expansion way: by manual;

- Punching way: Hydraulic pressing tool;

- Diameter of Punched Hole: according to customer’s request;

- Hole Distance: adjustable;

- Thickness of Material: 0.6-1.2mm;

- Rolling Stations: 12 Stations;

- Forming Speed: 0-15 m/min;

- Material of Roller: 45# steel coated with hard chrome;

- Material of Shaft: 45# Steel with tempering treatment;

- Transmission: by chain-brackets;

- Main Power: 5.5 KW;

- Cutting: Hydraulic cutting or tracking Fly-saw

- Hydraulic Power: 3KW;

- Material of Cutting Blade: Cr12 MOV Steel;

- Tolerance of Cutting Length: +/-2mm;

- Electricity: 380V/3ph/50HZ or as your request

- Control system: Delta PLC, Omron encoder

- Size of Console: 7500x1000mmx300mm;