Steel angle forming machine is made to manufacture angle beads batchfully in an automatic way. The machine in our company is made from high-quality steel and other qualitative materials which are procured from famous industries. We also have QC to check each step of making this machine, insuring the quality of steel angle forming machine.

Here is a video for your reference:

Slotted angle (also sometimes referred to as slotted angle iron) is a system of reusable metal strips used to construct shelving, frames, work benches, equipment stands and other structures. The name derives, first, from the use of elongated slots punched into the metal at uniform intervals to enable assembly of structures fixed with nuts and bolts, and second, from the longitudinal folding of the metal strips to form a right angle.

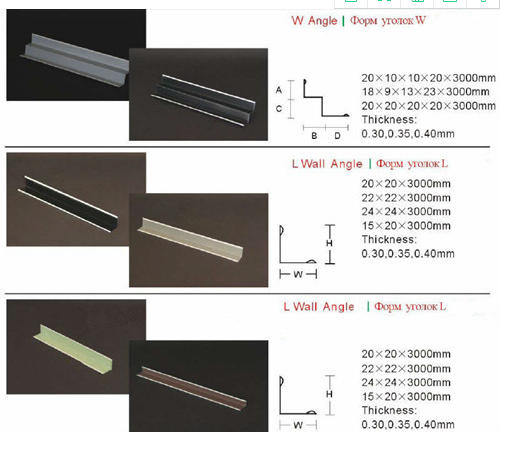

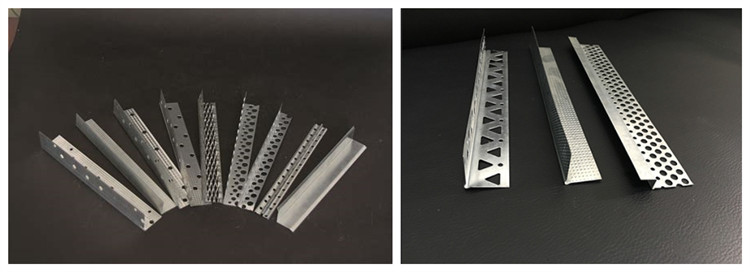

Here are some drawing profiles and finished product pictures for your reference:

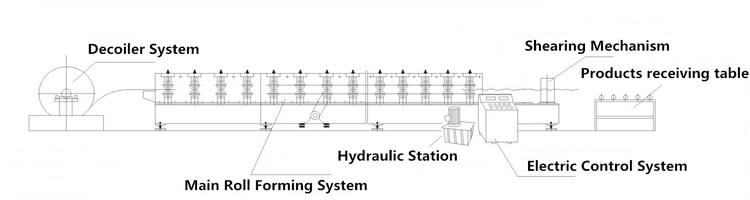

Working flow of steel angle forming machine:

Main technical parameters of slotted angle roll forming machine:

- Length of main part: 3500х800х1400

- Weight of main part: 3 tons

- Voltage: 380V/50HZ3Phase (as customer`srequest)

- Roller fixer: Guide column

- Frame thickness: 20mm

- Drive mode: gear

- Material of rollers: GCr12MoV

- Material of shafts: 45# steel with tempering

- Diameter of shafts: φ40mm

- Number of rollers: 9 rollers

- Main power: 3 kW

Detalied information of Steel Angle Forming Machine:

1. Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity: 5T

Uncoiling width: 500mm

Inner diameter: 450-550mm

2. Servo feeding and Punching part

Servo feeding power: 3kw

This part to punch the hole, you can change the mould to punch different holes.

Power:5.5kw

Punching:42T

Mould material : Gcr12MoV quenched

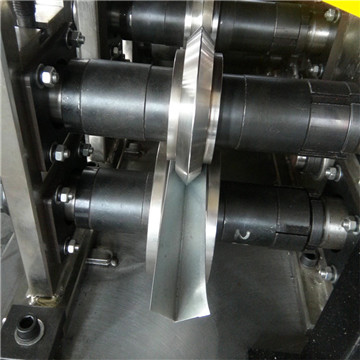

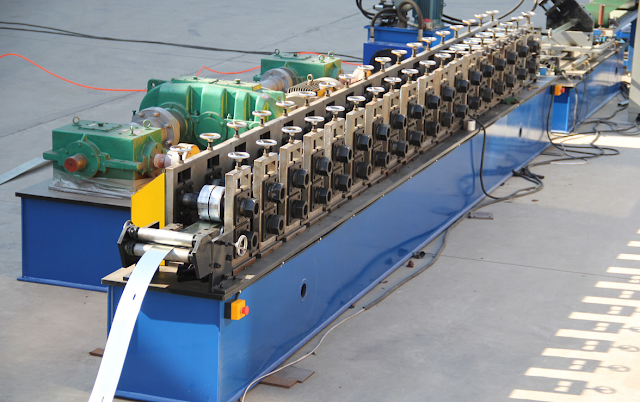

3. Slotted Angle Machine

Size: length*Width*Height – 13*1.3*1.7m

Weight t: 5 tons

Voltage:380V/50HZ3Phase(as customer`s request)

Roller fixer : Vertical arch

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

Drive mode:Gear driving

Material of rollers: GCR15 Aluminium processing after quenchin HRC58-62℃,Chrome plated

Material of shafts: 45# steel with tempering

Diameter of shafts: φ80mm

Number of rollers : 9 rollers

Main power: 7.5kw

Cycloidal planetary gear speed reducer)

Speed: 2-8m/min(not include cutting time)

4. Shearing system

Material of blades: Cr12Mov, herd steel HRC 58-62℃

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine.

6. Hydraulic station and PLC station

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves.

Feature:

- Adopted PLC, transducer, touch panel from Panasonic PLC to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

- Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.