Steel Door Frame Roll Forming Machine

This steel door frame roll forming machine is designed for making the metal door frame production in batch fully automatically.

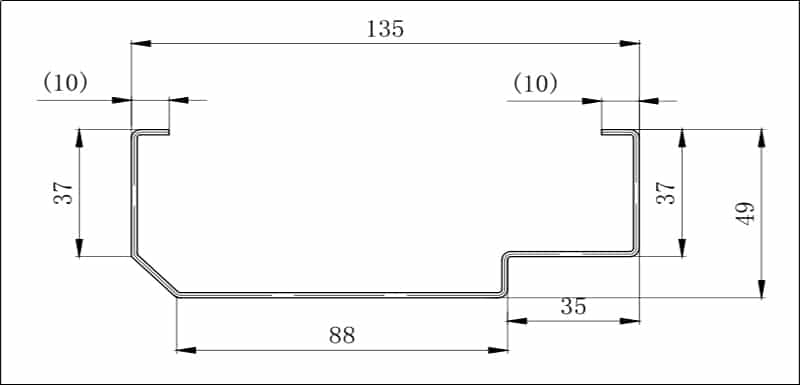

Steel Door frame drawing profile for your reference:

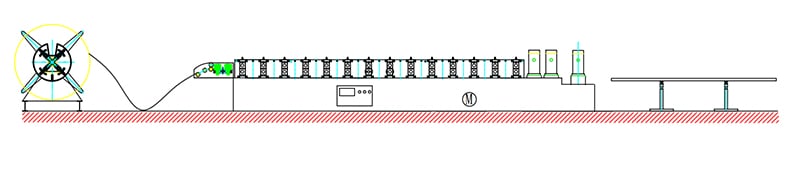

The Work Flow of the steel door frame roll forming machine

Decoiler→Feeding Guide Device Roll Forming System→Hydraulic

Post Punching & Cutting Device→Exit Rack

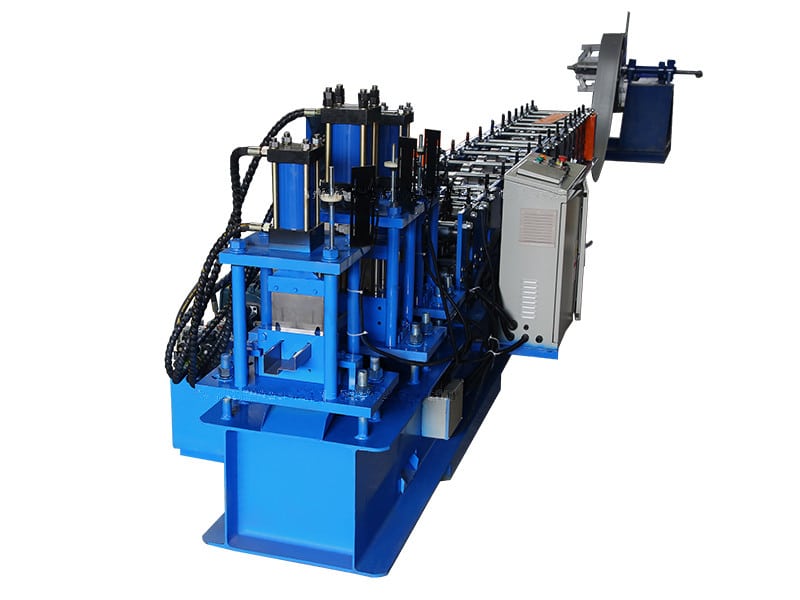

Based on the customer requirements and our experience, we design the steel door frame Roll Forming Machine like following picture:

The steel door frame Roll Forming Machine is composed by the following elements:

1)Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop Max

Feeding width:500mm,coil lD range 508mm士30mm Capacity:Max.3 Ton

2)Feed Guide Device

The guiding position can be adjusted for suitable material feeding.

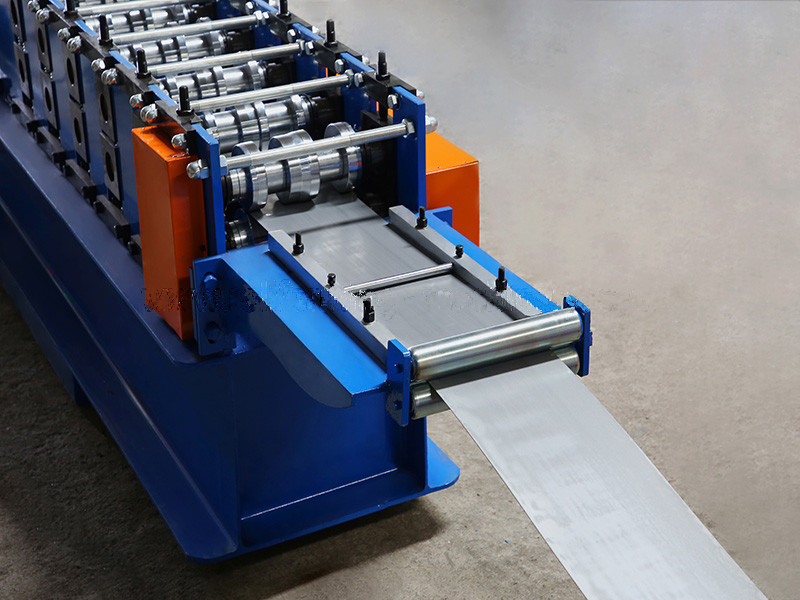

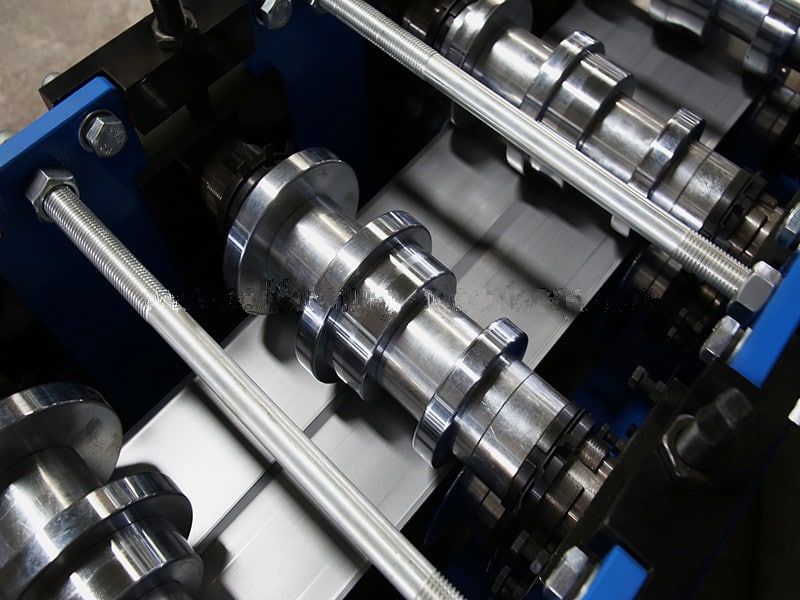

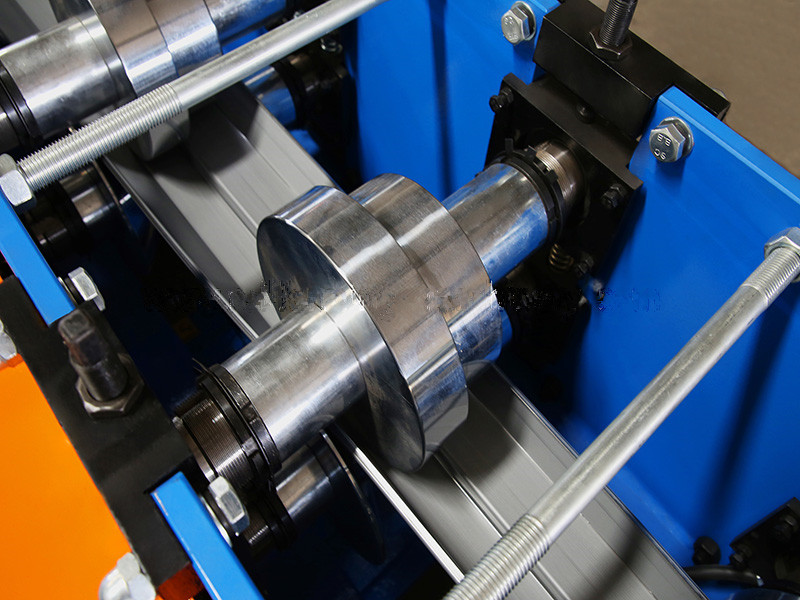

3)Main Machine

Body frame made from H450 type steel by welding

Side wall thickness: Q235 t18mm

Rollers manufactured from GCr15 Steel,Heat Treatment,HRC58-62

Shafts Diameter=φ75mm,precision machined

GearlSprocket driving,about 14-step to form

Main Motor(Polaroid brand)=11KW,Frequency speed control

Real forming speed:15-18m/min

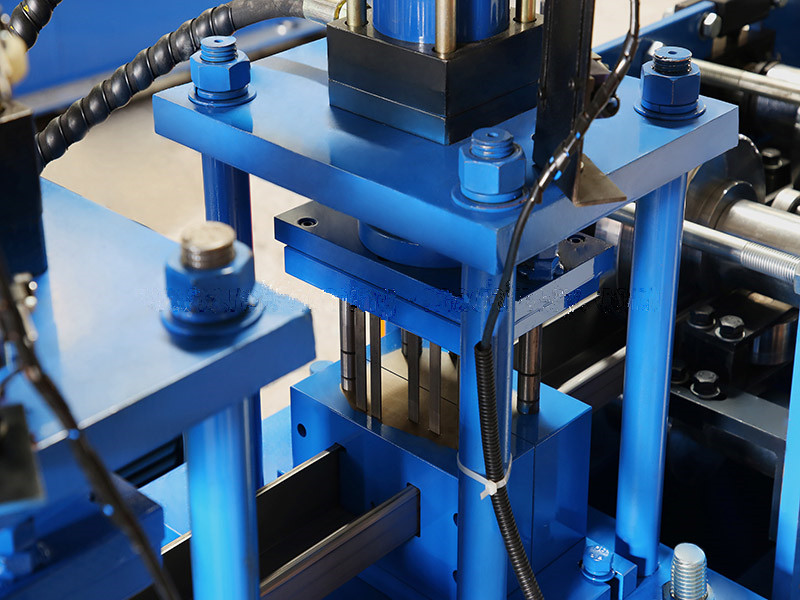

4)Hydraulic Post Punching &Cutting Device

Post to cut & Punch holes,stop to cutting & punching,Three pieces type of cutting blade design

Hydraulic motor: 7.5KW,Cutting And Puching Device Use The Same Hydraulic Station

Cutting & Punching moulds material: Cr12MoV(= SKD11 with at least one million times of cutting life),Heat treatment to HRC58-62 degree

The cutting power is provided by the main engine Independent hydraulic Station